In construction, inspections play a crucial role in ensuring that projects adhere to the highest standards of quality, safety, and compliance.

Despite meticulous planning and execution, construction projects may encounter inspection failures, posing significant challenges for project managers and stakeholders.

These failures not only disrupt the project timeline but also can lead to substantial financial losses.

Understanding and addressing these challenges is essential for the success and sustainability of construction projects.

Understanding Inspection Failures

Common Causes

- Non-Compliance with Codes and Regulations: Non-adherence to building codes and safety regulations is one of the primary reasons for inspection failures. This often occurs due to a lack of understanding of the latest regulations or negligence in their application. It’s crucial for construction teams to stay updated with code changes and incorporate them into their practices.

- Quality Control Issues: Deficiencies in material quality, workmanship, or construction practices often lead to inspection failures. Such issues can arise from inadequate supplier vetting, rushed work, or insufficient skill levels among workers. Implementing rigorous quality checks at every stage can mitigate these risks.

- Inadequate Documentation: Lack of proper documentation or failure to update records can result in failed inspections. This includes incomplete project records, missing permits, or outdated plans. Keeping meticulous and updated documentation is key to ensuring compliance and facilitating inspections.

- Communication Gaps: Miscommunication among team members or between contractors and inspectors can lead to oversight of critical aspects. These gaps can result from unclear instructions, language barriers, or lack of regular meetings. Effective communication is vital to prevent misunderstandings and ensure everyone is on the same page.

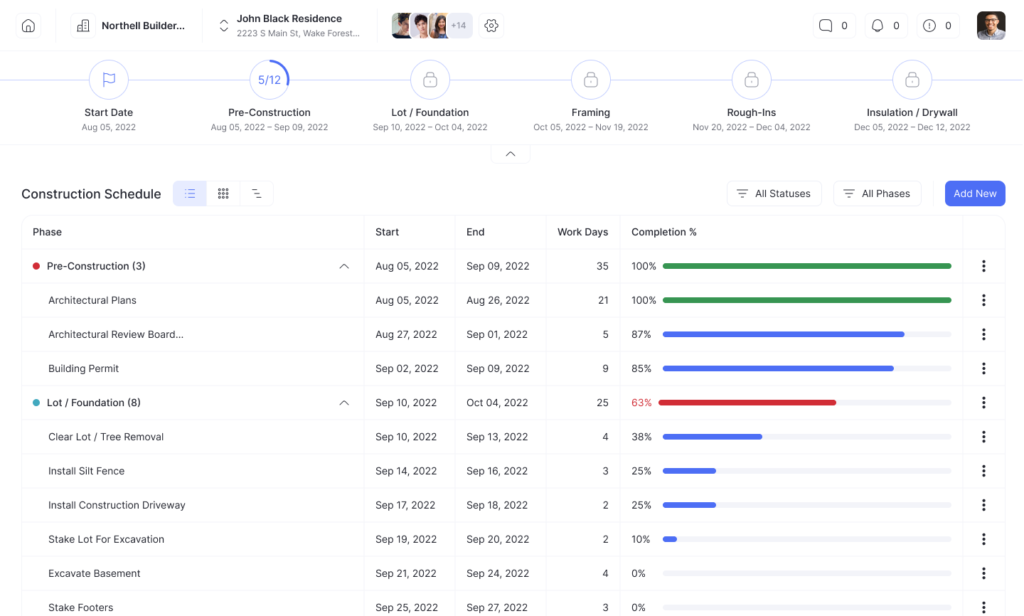

Builderpad will help you streamline communication to maximize transparency and mitigate any negative outcomes.

Impact of Failures

Inspection failures can have far-reaching consequences, including project delays, increased costs, legal complications, and reputational damage.

Delayed projects can strain client relationships and lead to financial penalties, while legal issues can arise from non-compliance with regulations.

Reputational damage can affect future business opportunities, making it imperative to address inspection failures promptly and efficiently.

Strategic Approaches to Resolve Inspection Issues

Immediate Response to Inspection Reports

- Thorough Review and Analysis: Analyze the inspection report in detail to understand the specific issues raised. This involves identifying the root causes of the problems and determining their impact on the project. A comprehensive analysis is crucial for developing an effective rectification plan.

- Quick Rectification Plan: Develop a corrective action plan, setting clear timelines and responsibilities for resolving the issues. This plan should prioritize the most critical issues and allocate resources accordingly. Immediate action demonstrates a commitment to compliance and quality.

Long-Term Preventive Measures

- Enhanced Quality Control: Implement stringent quality control measures and regular internal inspections. These measures should include checks at various stages of construction and involve multiple team members. Regular internal inspections can identify potential issues before they escalate.

- Training and Awareness: Conduct training sessions for workers and staff on compliance and best practices. This not only improves skill levels but also fosters a culture of quality and safety. Continuous education ensures that the team is aware of evolving industry standards and regulations.

- Effective Communication Systems: Establish robust communication channels among all parties involved in the project. Regular meetings, clear documentation, and open lines of communication can significantly reduce the risk of misunderstandings. Effective communication is key to coordinating efforts and ensuring project success.

- Utilizing Technology: Leverage construction management software for better tracking, documentation, and compliance. Technology can streamline processes, improve accuracy, and provide real-time updates. This not only aids in compliance but also enhances overall project management.

Collaboration and Professional Consultation

- Engaging with Inspectors: Foster a collaborative relationship with inspectors to gain insights into compliance requirements. Understanding an inspector’s perspective can help in preempting potential issues. Regular engagement with inspectors can also lead to more efficient and effective inspections.

- Consulting Experts: Seek advice from legal and industry experts to navigate complex regulations. This can include consulting with construction lawyers, engineers, or compliance specialists. Their expertise can provide valuable guidance and help avoid costly mistakes.

Case Studies and Best Practices

- Learning from Successful Projects: Analyze case studies where inspection challenges were effectively resolved. These real-world examples provide practical insights and proven solutions. Studying successful projects can also inspire innovative approaches to problem-solving.

- Adopting Industry Best Practices: Implement proven strategies and methodologies used in the industry to prevent inspection failures. This involves staying informed about industry trends and adopting best practices from leading construction firms. Embracing these practices can significantly enhance project outcomes.

Conclusion

Inspection failures, while challenging, provide an opportunity for construction professionals to enhance their practices and ensure the highest standards of project execution.

By adopting a proactive approach, engaging in continuous learning, and leveraging technology, construction managers can effectively navigate and resolve.

Takeaways

- Understanding and adhering to building codes, safety regulations, and quality standards is crucial to avoid inspection failures. Construction teams should stay updated on evolving regulations and incorporate best practices.

- Inspection failures can lead to major delays, increased costs, legal issues, and reputational damage. It’s critical for project managers to respond promptly and efficiently to resolve inspection issues.

- A thorough analysis of inspection reports is needed to identify root causes and develop corrective action plans. Priority should be given to addressing the most serious deficiencies first.

- Implementing rigorous quality control, training programs, robust communication systems, and construction software can help prevent future inspection failures.

- Fostering collaboration with inspectors and consulting experts provides valuable guidance on compliance requirements and avoiding oversight.

- Studying case studies and adopting industry best practices are effective ways to learn from other successful projects and enhance inspection preparedness.

- While challenging, inspection failures present opportunities for continuous improvement in policies, processes, and skills to execute projects to the highest standards. A proactive mindset is key.